Jar Filler and Capper

Jar Filler and Capper

Description

Item # 8494 - FILLER AND CAPPER

used previously for filling chutney, cooking sauces, pastes, marinades, etc in various different jar sizes for supermarkets.

2000 to 3000 jars per hour depending on the size of the jar and the filling volume.

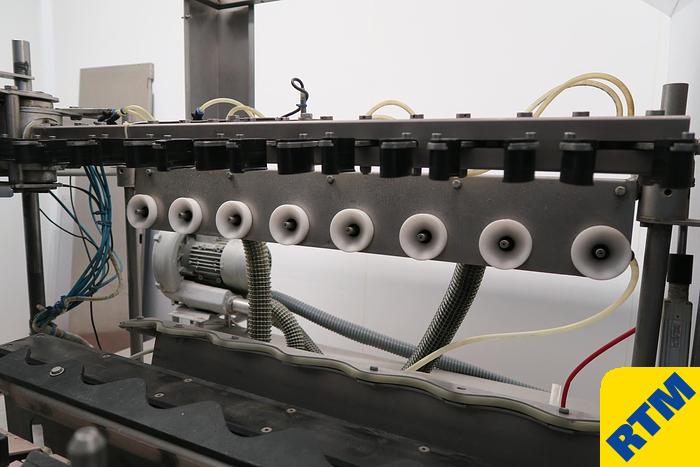

The jars are loaded on an eight lane conveyor, from there jars are picked and air blown inside to clean any foreign body inside, depositor fills the jar and forwards it to the capper where the steam in injected to sterilize the top void and twist cap is applied. Volumes of 190ml up to 700ml were made with this line (details of the jars and caps are included with the photos)

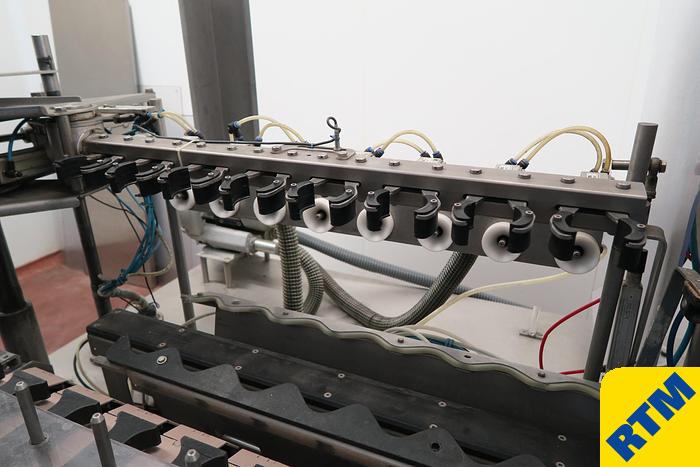

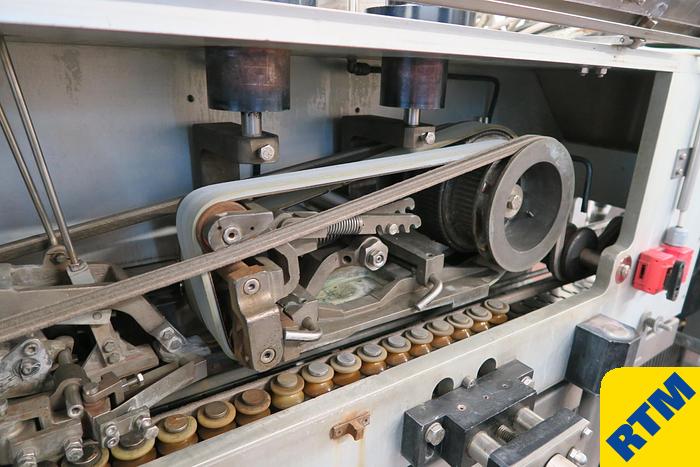

L.S. (Italy) mono-block incorporating 8-lane jar feeder (manually loaded) into air blown jar cleaner into 4-head jar filling machine - piston filler

Year 2009, Model L-8-PF-4.

Siemens Simatic Touch screen PLC

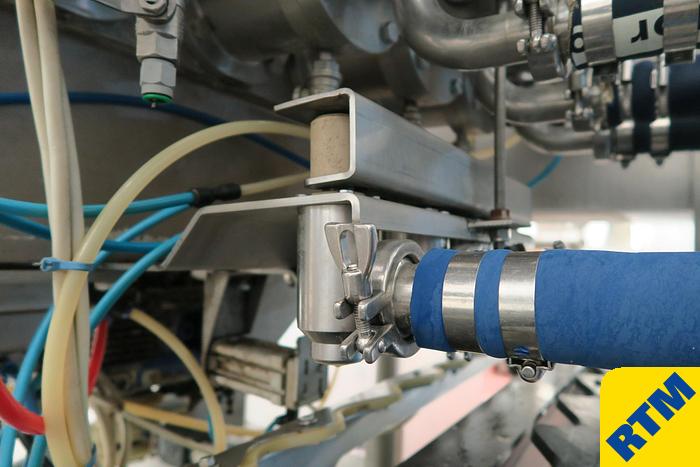

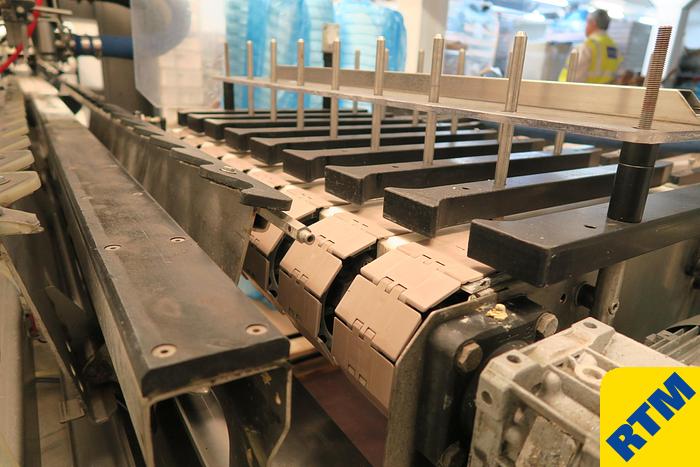

L.S. (Italy) capping machine Type Twist-Off Capper model LT-100, serial number IC01M31-09 year 2009.

The capping machine has steam injection for sterilisation

With 3Master type ALN-200-200 cap infeed hopper/elevator

Last used in production in May 2017. NOW DISMANTLED AND IN STORAGE

Line is 415volt, 50hz, 3ph

Specifications

| Manufacturer | L.S. / IC |

| Condition | Used |

| Stock Number | 8494 |