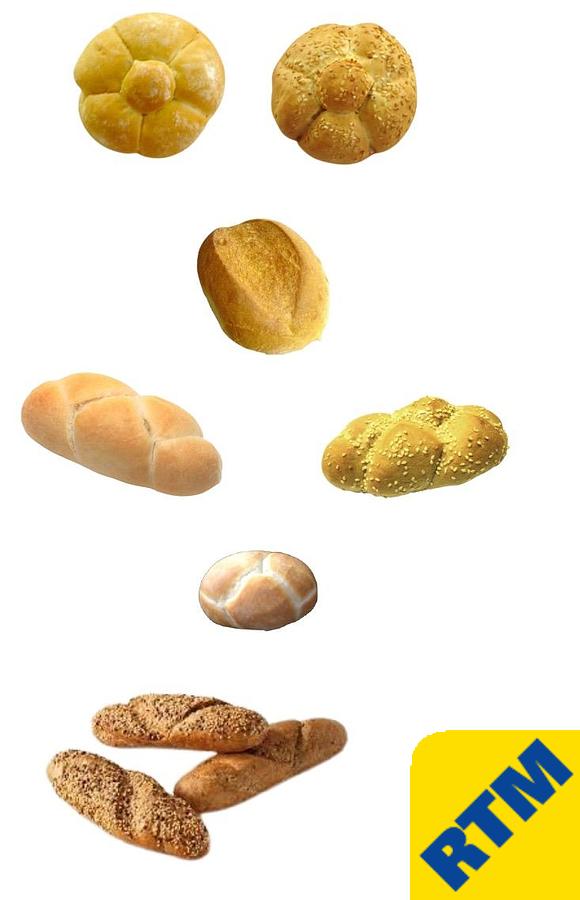

LINE TO PRODUCE STAMPED ROLLS, BUNS & MINI-BAGUETTES

LINE TO PRODUCE STAMPED ROLLS, BUNS & MINI-BAGUETTES

Contact us for price

Description

Item # 9229 - LINE TO PRODUCE STAMPED ROLLS, BUNS & MINI-BAGUETTES

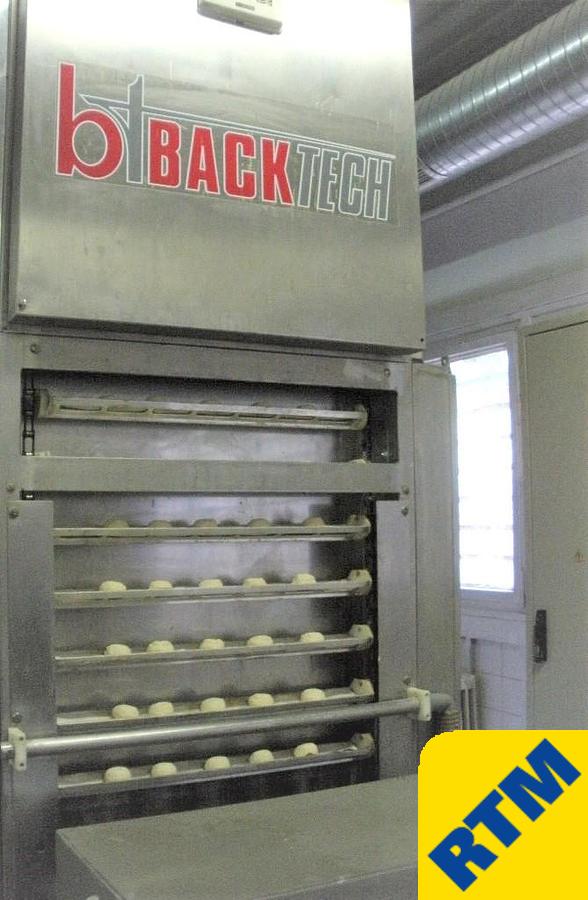

Manufactured by BACKTECH

Was being used to produce frozen part-baked products

Products with a weight of 40 to 90grammes

Designed for one person operation

Machinery built in Year 2002

Capacity up to 6000 pieces, depending on product & weight

With

APV PAVAILLER Spiral Mixer, Model S125CF, 200Kgs capacity, fixed bowl, 2-speed forward, 1-speed reverse

Line also includes :

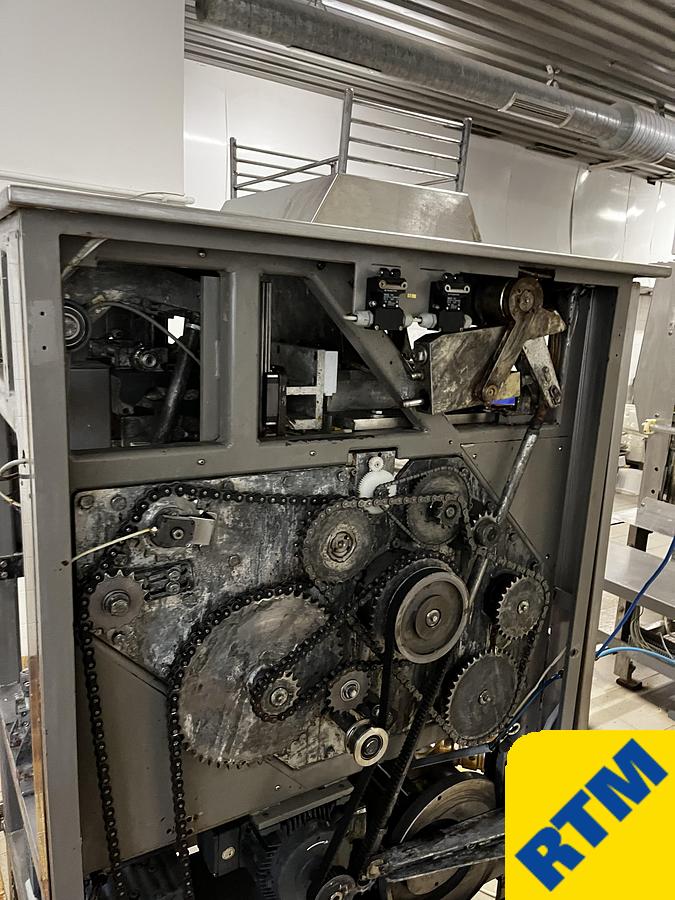

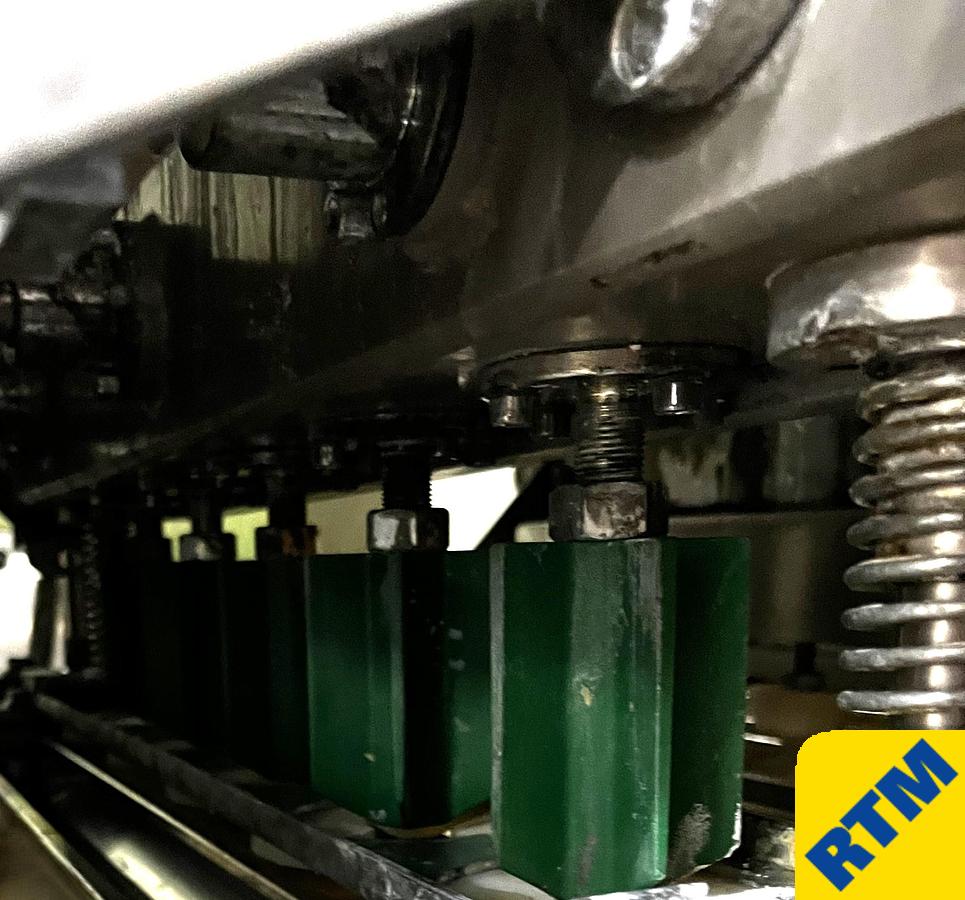

Mega-Star Model: MS 5/30-100

Dough divider moulder with 5 pockets

Manual feeding through a hopper

Quickly interchangeable dividing pistons

Belt round moulder

Exterior moulding drums (honeycomb drum)

Touch-screen control for recipes adjustment

Height of the spreader belts: 800 mm

Weight (approx.): 900 kg. Power: 1.5 kW. Size (W x L x H): 900 x 1530 x 1750 mm.

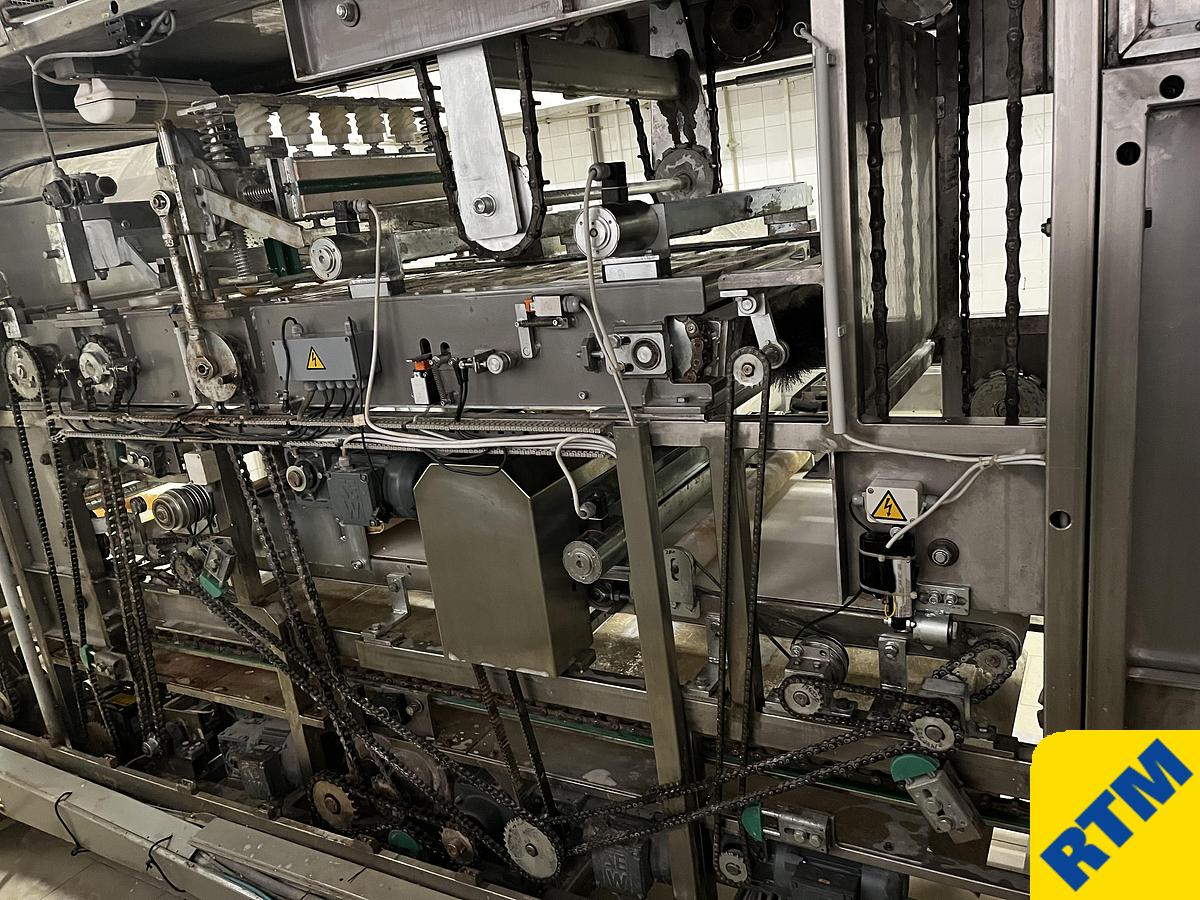

Vario-Star Duo Model: VSDK/L 5-4-3

Output: 6000- 4800- 3600 round and long formed rolls

10 to 11 minutes resting (pre-proofing) time

200 active proofing cups

Temperature and humidity control

Separate moulding units for round and the long rolls

Direct switchover from one proofing mode to another

Forming tools for rosetta, kaiser rolls, special shape, rustical bread

En block final proofing cabinet

Power: 7.5 kW. Weight: (approx..): 1950 kg. Size (L x H): 4940 x 2830 mm.

Combi-Star, Model: CSL 20/390

Final proofer

20 minutes proofing time

Temperature and humidity control

Décor-Star, Model DS 600

Wetting by wetting roll, water fed by spray nozzles

Seeds are sprinkled by seeder

6 hoppers for seeding materials

Trolley for the hoppers

Stainless steel container for collection of excess seed

Power: 0.6 kW. Working width: 600 mm. Size (L x H): 750 x 1180 mm.

Mono-Star, Model: MS 600/1

Panning with retracting belt

With computer and pieces counter

For maximum tray size 580 x 980

Weight: 1220

Power: 2 kW. Size (L x H): 1680 x 940 mm.

Robo-Star, Model RS 58/98

Fully automatic tray loading system

Removes the empty tray from the rack and deposits it in the depositing area of the roll plant

Removes the filled tray and place it in the rack.

Possibility to work with various trolley designs.

Also including :

20 x Stainless Steel racks for Robo-Star, for 18 trays dimensions 600 x 800mms

200 x Flat Perforated Flat trays for Robo-Star, teflon, 600 x 800mms

60 x Corrugated & Perforated trays for baguettes, teflon, 600 x 800mms

1000 x Plastic Stackable Trays for rolls, Stackable nest bun trays in two dimensions: 640 x 540 x 117 mm and 640 x 540 x 96 mm,

Ventilated base and walls, Two open hand holes, Suitable for storing and freezing products, Working temperature: - 40 ֯C - +70 ֯C, Material – High density polyethylene (HDPE).

The line was half-dismantled for cleaning and maintenance a month ago, but it can be put in operation easily.

could also be available are the fermentation chamber (built-in), rotary oven, shock freezer, 20 sq m storage freezer.

Specifications

| Manufacturer | Backtech |

| Year | 2002 |

| Condition | Used |

| Stock Number | 9229 |