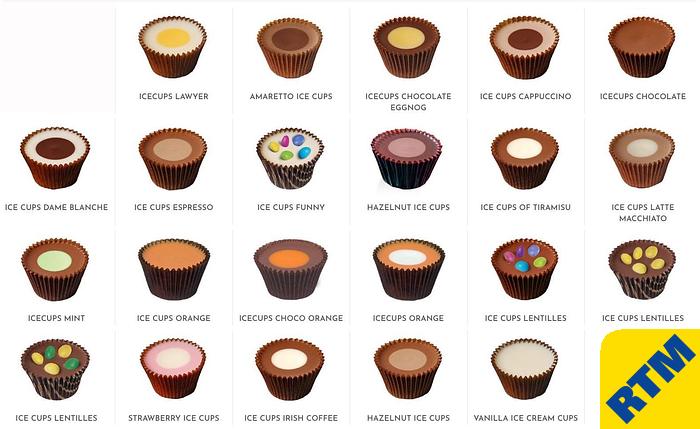

LINE TO MANUFACTURE AND PACK CHOCOLATE ICE CUPS

LINE TO MANUFACTURE AND PACK CHOCOLATE ICE CUPS

Description

Item #8926 – LINE TO MANUFACTURE AND PACK CHOCOLATE “Ice Cups”

Compound chocolate deposited in a paper cup for quick-melt cool mouthfeel

The line has two chocolate depositors for different colours and a depositor for decorations

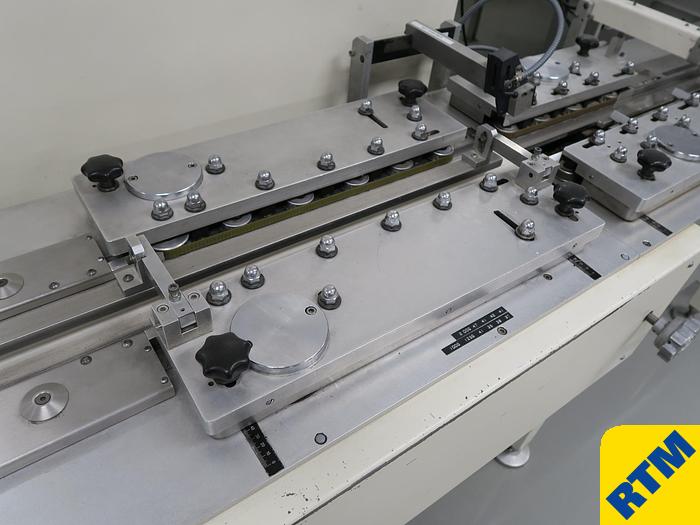

380mms working width x 280mms depth mould

Each Mould holding 9 x 6 products, so 54 products per mould

Each product/cup around 10grammes

Including:

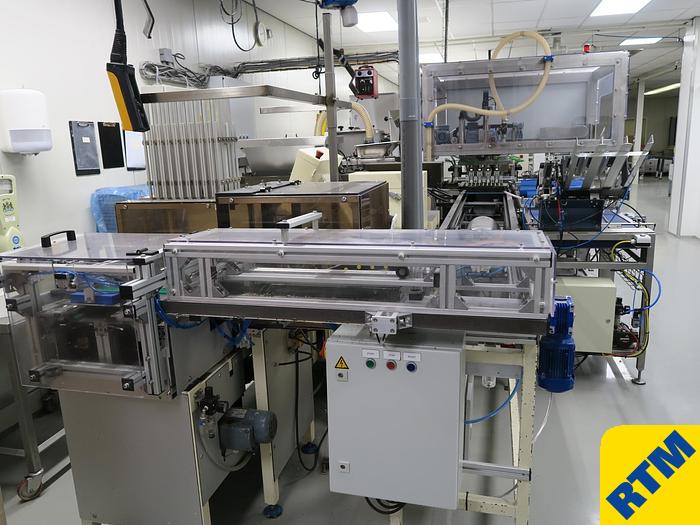

PROMETAG ST-KA-01 Empty Nest/Case Hoppers, placing the empty cases into the moulds, 2 x 9 rows, with vacuum pump.

KNOBEL CCM-24 Depositor, PLC Controlled, with 24 Dosing pumps.

Then through a Product Decorator/Depositor, with vacuum pump, for optionally picking & placing mini candies (like smarties/m&ms) on top of filled cup.

KNOBEL CCM-9 Decorator, for optionally depositing small decoration on top of filled cup.

HOUGKOELING Cooling Tunnel, with 2 x transport bands, with 180degree conveyor, cold air cooling down to 4degrees C.

HDC Product Pick N Place De-Moulding from moulds, year 2015, with vacuum pump, SIEMENS Simatic Panel PLC controls

Placing of products into Plastic Trays, with

PROMETAG Tray De-Nesting Machine, Type UE-3, 3-Lane

FLEXWAY Mould Transfer Conveyor, taking empty moulds back to start of line.

RT4 Infeed Conveyor through to a

TEVOPHARM P5 Flowpack Wrapper, rebuilt by TEHAMA, with a KORTHO HotPrinter Coding Unit.

LOCK 30+ Metal Detector, and an

ISHIDA DACS Checkweigher with printer, up to 1200grammes,

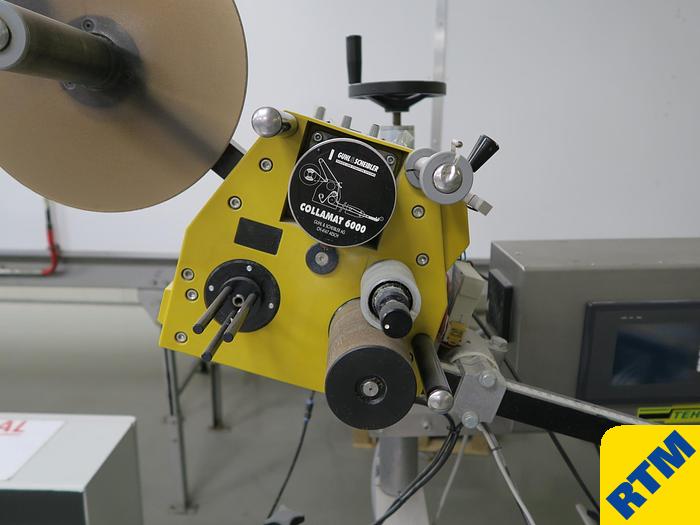

GUHL & SCHEIBLER Collamat 6000 Top & Bottom Label Applicator.

optionally available with

(2) CHOCOLATE BALL MILLS used for compound chocolate manufacture on the ice cup line

Manufactured by WIENER

Model WIENEROTO 30S

a jacketed grinding tank, the inner tank made of stainless steel, designed for cooling or heating purposes (pressure-less),

total gross volume 200 litre, net volume 50 to 90 litre, provided with bottom discharge,

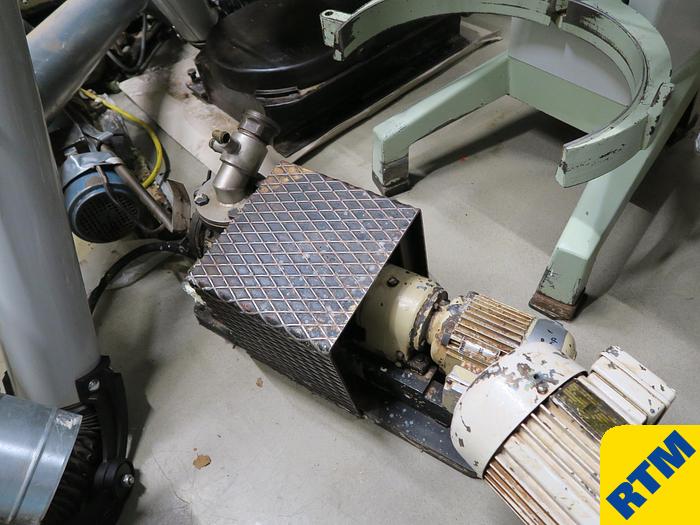

drive unit with 15 HP electric motor, a stepless adjustable 1 :3 variator, toothed belt transmission, a plate coupling and a worm gearbox

were run at 4 batches of 65 kg in one hour. grinding to circa 20 microns

Heating, Cooling, and with Stainless Steel Mixing Arm

Adjustable Speed, with 600Kgs of steel balls in each tank

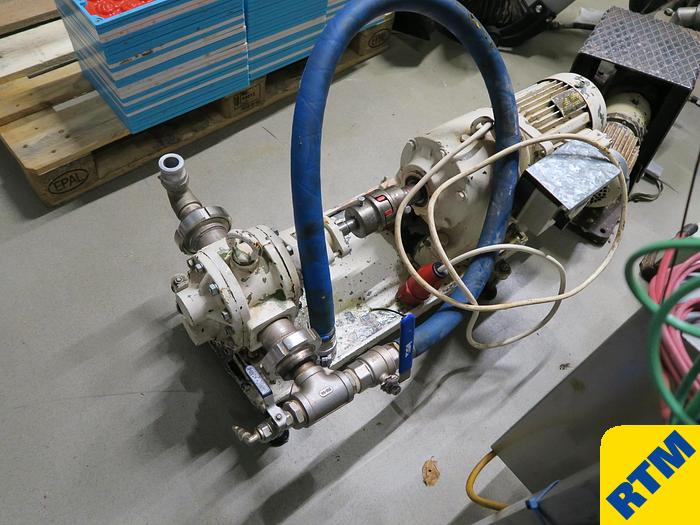

Each with control cabinet, each with Pump

Specifications

| Condition | Used |

| Stock Number | 8926 |