CEREAL FLAKING/ MICRONIZING LINE

CEREAL FLAKING/ MICRONIZING LINE

Description

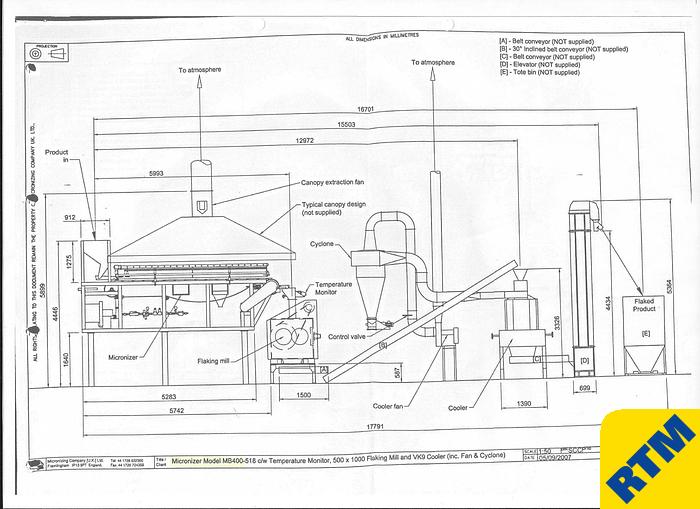

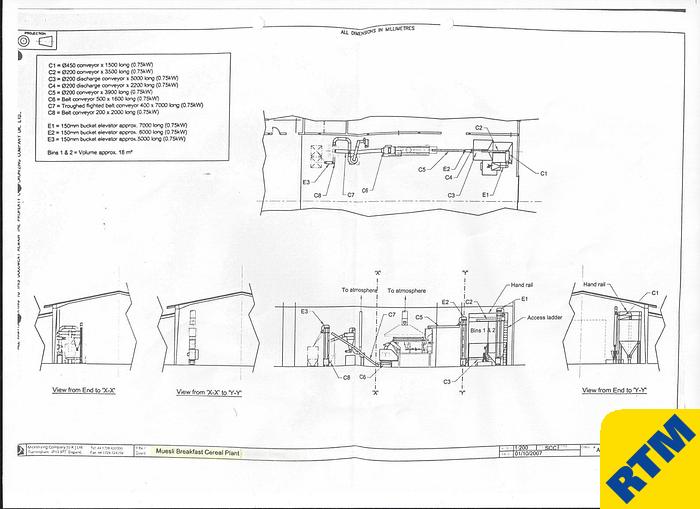

Item # 8576 - CEREAL FLAKING/ MICRONIZING LINE

Nominal capacity 400 kg/hr.

Flaking Line from MICRONIZING in the UK - this being used for the flaking of CEREALS.

Equipment was installed from summer time 2008 on and has been running a limited number of hours only

Infra Red Micronizing is a patented dry thermal process based on short wave lengths of 1.8 - 3.4 microns. It is related to a specific part of the electro-magnetic spectrum that concerns Wavelength and Frequency of the Micronizing process.

The Micronizing System is designed to be a fail safe, low maintenance cooking process. When running on a daily basis (8 hours per day), the only operator involvement at the Micronizer is for start up.

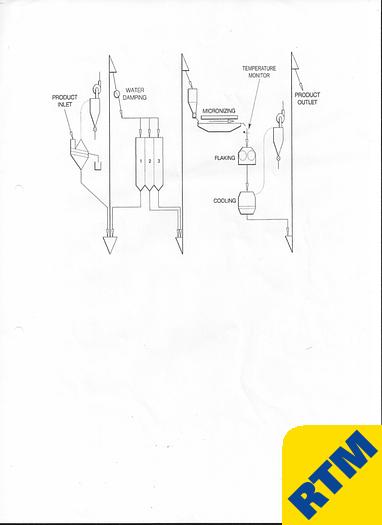

this line hasn't been fully used in all the years, it is still in a good working condition and the process flow reads as follows:

- cleaning and aspiration of raw materials;

- variable percentage water addition to raw materials as required;

- tempering period for proper water absorption;

- prepared raw materials supplied to the Micronizer via a hopper and a variable speed feeder;

- process parameters and temperatures are PLC or manually controlled and adjusted accordingly;

- gas controls, air pressures, fuel flow, material availability, infrared failure, motor rotations are all constantly monitored as fail safe “limits” by the ignition controller system;

- cooked Micronized materials fall directly into a heavy-duty flaking mill, residual cooking vessel or winnower, depending on the application. Hydraulics control “open and close” roll gap function automatically;

- cooked Micronized products are cooled in a counter flow cooler to ambient +5 degrees C;

Specifications

| Condition | Used |

| Stock Number | 8576 |