BREAKFAST CEREAL LINE (CRUESLI TYPE PRODUCT)

BREAKFAST CEREAL LINE (CRUESLI TYPE PRODUCT)

Description

Item # 8577 - BREAKFAST CEREAL LINE (CRUESLI TYPE PRODUCT)

Line produces crunchy muesli product made by mixing muesli with oil or butter and sugar, bake honey or a sugar substitute. The cookies that arise are broken into small pieces.

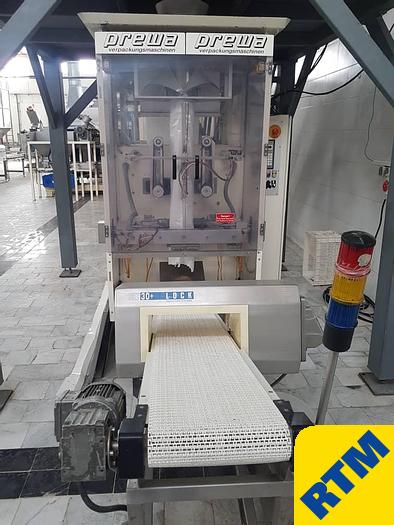

(from the dry ingredients handling up to and inclusive the 4 head PREWA (Germany) bagging machine with 4 inline weighers and metal detector. The line hasn't been fully used in all the years and is still in a good working condition and consisting of:

Equipment was installed from summer time 2008 on and has been running a limited number of hours only

A) SYRUP SYSTEM to suit 500 kg+/hr. CRUESLI LINE, comprising:

- 1 st. steel MIXING TANK - 230 ltr., jacketed (double wall) design for hot water heating system, incl. of pump, protective cover, etc.;

- PIPEWORK from mixing tank to holding tank, incl. of butterfly valves, drain, re-circulating pipe, etc. All st.steel and jacketed (double wall) design to suit hot water heating system;

- 1 st. steel HOLDING TANK - 230 ltr., jacketed (double wall) design to suit hot water heating system, incl. of pump, protective cover, etc.;

- PIPEWORK from holding tank to enrober; all pipework jacketed (double wall) design, spraying nozzles, etc.;

- 1 st. steel OIL TANK - 230 ltr., jacketed (double wall) design to suit hot water heating system, incl. of pump, protective cover, etc.;

- PIPEWORK from oil tank to enrober, incl. of butterfly valves, volumetric controller, spraying nozzle, drain, jacketed design, etc.;

- 1 CONTROL PANEL containing direct-on-line starters for above drive units;

B) DUMP STATION to suit 500+ kg/hr. CRUESLI LINE, comprising:

- one DUMP Station (comprising 3 pallet positions and 5 silos complete with vibratory feeder to control quantity of ingredients;

- 1 inclined BELT ELEVATOR to transport product from dump station to the enrober;

- 1 FRAMEWORK incl. staircase for feeding system (in front of dryer) to also hold the 2 following items;

- 1 ENROBER model Q for the correct mixing of all CRUESLI ingredients, incl. of spraying nozzles, etc.;

- 1 OSCILLATING SPREADER facility onto the conveyor belt of the WOLVERINE PROCTOR Dryer;

- 1 PRIMARY BREAKER (at delivery end of dryer) to break product layer into smaller pieces;

- 1 high pressure CLEANING SYSTEM (to keep conveyor belt clean);

- 1 VIBRATORY CONVEYOR designed to size the product in 3 different sizes and transport the product from Dryer to the elevator conveyor;

- 1 ELEVATOR to transport product from vibratory conveyor to the dump station, complete with 2 discharge chutes, etc.;

- 1 SCREW type of conveyor to transport oversized product to secondary breaker, complete with chute, etc.;

- 1 SECONDARY BREAKER to break oversized product coming from the vibratory conveyor, complete with hopper for collection;

- 2 movable STORAGE SILOS 1 x 1 x 1.5 m provided with sight glass, protective cover and manually activated shut-off gate;

- 1 VIBRATORY FEEDER for nuts to transport nuts and other additives to the vibratory conveyor;

- 1 VIBRATORY FEEDER for raisins to transport raisins and other additives to the vibratory conveyor;

- 1 POWER CONTROL CUBICLE containing direct-on-line starters for the drive units of all above equipment as well as the controls for the gas burners of the dryer;

C) WOLVERINE PROCTOR SCF type of DRYER to suit 500+ kg/hr. CRUESLI LINE, comprising:

- 1 WP conveyor DRYER with nearly 2 m wide travelling conveyor for the cruesli mass - dryer designed to suit direct natural gas firing by means of 2 burners - and appr. overall length of 10.2 m;

- 1 rotary PRODUCT LEVELLER mounted over the infeed end, immediately behind the oscillating spreader;

- conveyor plates and travelling guides provided with ELECTROPOLISHING in order to create a non-sticking character of the belt;

D) PREWA vertical packaging machine with 4 inline weighers and packing heads. Furthermore provided with feeding conveyor work and a Metal Detector (UK made); in principle the bagger and 4-lane weighers can run on weights ranging from 50grs. - 1 kg. Actually they run at a speed of some 30 bags/min. of 375 grs. - equal to over 650 kg/hour...

Specifications

| Condition | Used |

| Stock Number | 8577 |